Propylene Oxide is one of the most critical chemical intermediates in the U.S. petrochemical industry. As a core raw material for polyurethane foams, propylene glycol, and other downstream derivatives, propylene oxide supports key sectors such as construction, automotive, furniture, electronics, and packaging.

By 2026, the U.S. propylene oxide market is experiencing a structural shift. Environmental regulations, rising sustainability expectations, and increased investment in advanced propylene oxide production technology are reshaping competition among propylene oxide manufacturers. Today, leadership in the U.S. propylene oxide industry is determined not only by production scale, but also by technology adoption, vertical integration, and long-term supply reliability.

This article provides a data-driven overview of the top propylene oxide manufacturers in the USA, while also examining market trends, production technologies, and competitive dynamics shaping the industry in 2026.

Propylene oxide is a highly reactive epoxide primarily used as an intermediate rather than a finished chemical product. Its strategic value lies in the diversity of its applications and its essential role within the petrochemical value chain.

The largest share of propylene oxide consumption is driven by:

Polyurethane foams, used extensively in furniture, bedding, automotive interiors, insulation panels, and energy-efficient buildings

Propylene glycol, a key ingredient in food, pharmaceuticals, cosmetics, antifreeze, and industrial heat-transfer fluids

Other derivatives, including glycol ethers and polyether polyols used in coatings, adhesives, sealants, and elastomers

Because of these applications, propylene oxide is widely recognized as a strategic chemical intermediate that supports both consumer and industrial markets across the United States.

In the U.S., propylene oxide production benefits from strong downstream integration, abundant propylene feedstock, and proximity to major end-use industries. By 2026, demand for propylene oxide is increasingly influenced by sustainability goals, making production efficiency and low-emission processes more important than ever.

The United States remains one of the largest producers and consumers in the global propylene oxide market. The U.S. propylene oxide market is characterized by high capital intensity, limited numbers of suppliers, and strong integration with downstream polyurethane and specialty chemical manufacturing.

Stable growth supported by construction, insulation, and automotive demand

Increased use of polyurethane foams for energy-efficient buildings

Rising domestic demand for propylene glycol in food and pharmaceutical applications

Most propylene oxide production in the USA is concentrated along the Gulf Coast, particularly in Texas and Louisiana. This region benefits from:

Direct access to propylene feedstock

Established petrochemical infrastructure

Efficient logistics for domestic distribution and export

As a result, the U.S. market is largely supplied by domestic propylene oxide manufacturers, reducing reliance on imports and enhancing supply chain resilience.

Production technology plays a decisive role in the competitiveness of propylene oxide production companies in the United States.

The chlorohydrin process was historically the dominant method for propylene oxide production. However, it is associated with:

High energy and water consumption

Generation of chlorinated by-products

Increasing environmental compliance costs

The HPPO (Hydrogen Peroxide to Propylene Oxide) process has become the preferred modern alternative. This advanced propylene oxide production technology offers:

Significantly lower environmental impact

Reduced waste streams

Improved operational efficiency

By 2026, manufacturers that have adopted HPPO or similar sustainable propylene oxide production methods enjoy long-term cost advantages and stronger positioning with environmentally conscious customers.

To identify the top propylene oxide manufacturers in the USA, we evaluated companies based on multiple structural and strategic criteria rather than short-term output alone. These include:

U.S. production capacity and manufacturing footprint

Adoption of advanced propylene oxide production technology

Degree of downstream integration

Long-term investment strategy and operational stability

Strategic role within the U.S. chemical supply chain

Wuxi High Mountain Hi-tech Development Co., Ltd., operating as High Mountain Chem, was established in 1992 as a professional industrial enterprise dedicated to specialty chemical production, technology research & development, and import-export trade. The company specializes in organic intermediates, with a strong emphasis on high-purity Propylene Oxide (also known as Epoxypropane or Methyloxirane, CAS 75-56-9). As a reliable Propylene Oxide supplier in China, High Mountain Chem supports global industries including pharmaceuticals, agrochemicals, pesticides, and specialty chemicals through consistent production and optimized supply chain management.

High Mountain Chem is certified under GB/T19001-2016/ISO 9001:2015 quality management systems and has been repeatedly recognized as a Jiangsu High Tech Enterprise and Private Science & Technology Enterprise. Key milestones include pioneering exports of select chemicals and building long-term strategic partnerships with major domestic and international enterprises, ensuring stable Propylene Oxide supply with stringent quality controls.

With over three decades in the chemical sector, High Mountain Chem has extensive experience in Propylene Oxide handling, distribution, and application support. The company has successfully optimized international marketing networks, providing differentiated, high-quality Propylene Oxide solutions to clients while maintaining competitive pricing and reliable delivery.

Supported by specialized teams in export, import, logistics, and quality assurance, High Mountain Chem draws on 20+ years of deep industry expertise. Its robust R&D capabilities enable customized Propylene Oxide formulations, agile innovation, and continuous improvement to meet evolving market needs in propylene oxide production and related intermediates.

Key Products in Propylene Oxide and Related Categories:

Propylene Oxide

Epichlorohydrin

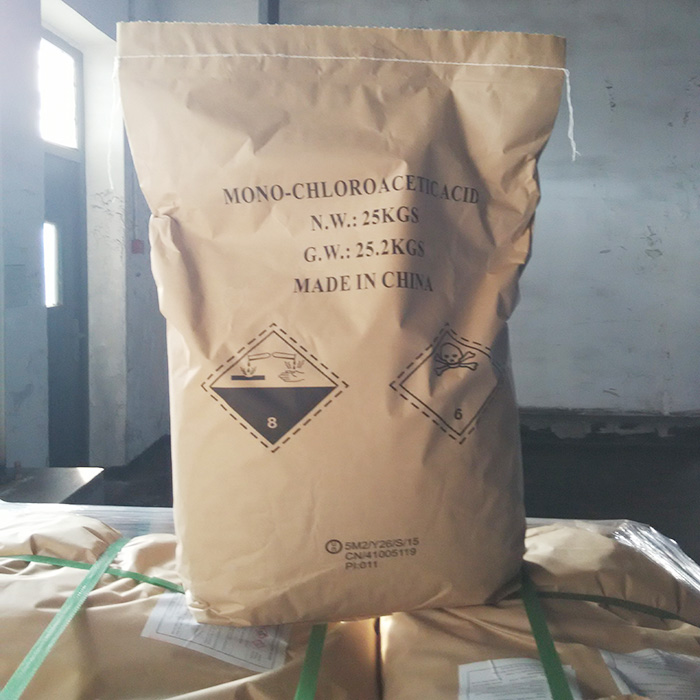

Chloroacetic Acid

Paradichlorobenzene

Thiourea

LyondellBasell Industries N.V. (NYSE: LYB) is a global leader in the chemical industry, specializing in the production of polymers, plastics, chemicals, and refining products. Headquartered in Houston with significant operations worldwide, the company is one of the largest producers of polyolefins and a pioneer in polyolefin technologies. As a prominent propylene oxide manufacturer, LyondellBasell operates advanced facilities utilizing proprietary PO/TBA (propylene oxide/tertiary butyl alcohol) technology, including the world's largest propylene oxide production plant in Channelview, Texas, with an annual capacity of approximately 470,000 metric tons.

LyondellBasell holds a strong position as the world's largest licensor of polyolefin technologies, with over 350 licensed production lines globally. The company excels in propylene oxide production and is recognized for its contributions to sustainable solutions, including advancing circular and low-carbon initiatives. It has earned accolades such as ESG leadership rankings and supply chain excellence awards, while committing to ambitious goals like net-zero emissions by 2050 and scaling recycled/renewable-based polymers.

With decades of expertise in propylene oxide manufacturing, LyondellBasell has successfully developed and operated large-scale propylene oxide plants, including the landmark PO/TBA facility in Texas that sets industry benchmarks for efficiency and capacity. The company's experience extends to global sites supporting propylene oxide production chains, delivering reliable supply for downstream applications in polyurethanes and related industries.

Led by an experienced executive team, including a dedicated Chief Innovation Officer, LyondellBasell invests in global R&D and technology centers to drive advancements in propylene oxide technologies and sustainable materials. The innovative team focuses on proprietary processes like PO/TBA to enhance production efficiency and support customer needs in evolving markets.

Key Products in Intermediates and Derivatives

Propylene Oxide

Tertiary Butyl Alcohol

Styrene Monomer

Oxyfuels

BASF Corporation serves as the North American affiliate of BASF SE, the world's largest chemical producer headquartered in Germany. With approximately 16,000 employees across more than 100 production and R&D sites, the company generated $19.7 billion in sales in 2024. BASF Corporation draws on BASF Group's global leadership as a top propylene oxide manufacturer, delivering innovative petrochemical solutions with a focus on sustainability and customer-enabled green transformation in the chemicals sector.

BASF stands out among propylene oxide manufacturers for its pioneering Hydrogen Peroxide to Propylene Oxide (HPPO) process, developed jointly with Dow. This breakthrough earned the 2010 U.S. Presidential Green Chemistry Challenge Award for Greener Synthetic Pathways. The HPPO technology significantly reduces wastewater by 70–80%, energy consumption by 35%, and eliminates unwanted coproducts, establishing BASF as a benchmark in sustainable propylene oxide production.

BASF brings decades of expertise in propylene oxide manufacturing, with the first commercial-scale HPPO plant commissioned in Antwerp, Belgium, in 2008—the world's largest at the time. Additional facilities in Asia, including Thailand, showcase proven large-scale propylene oxide production capabilities. These projects highlight reliable, high-yield operations serving global demand for propylene oxide in polyurethanes and derivatives.

BASF's expert teams drive continuous innovation in propylene oxide technology, emphasizing eco-efficient processes and advanced catalysts. Collaborations, such as the long-term HPPO joint venture with Dow, foster cutting-edge advancements that reinforce BASF's position as a forward-thinking propylene oxide manufacturer committed to environmental responsibility and performance excellence.

Key Products

Propylene Oxide: high-purity production and global supply

Propylene Glycols: downstream derivatives from propylene oxide

Polyether Polyols: propylene oxide-based precursors for polyurethane foams

Glycol Ethers: applications derived from propylene oxide manufacturing

Shell Chemicals, the petrochemicals arm of Shell plc, has over 90 years of expertise in the global chemicals industry, dating back to its founding in 1929. As a prominent Propylene Oxide Manufacturer, Shell excels in Propylene Oxide Production through its proprietary Styrene Monomer/Propylene Oxide (SM/PO) process, which efficiently co-produces Propylene Oxide and Styrene Monomer. The company operates world-scale facilities across multiple continents, supplying high-quality Propylene Oxide and its derivatives to industrial customers worldwide, supporting applications in polyurethanes, automotive, construction, and consumer goods sectors.

Recognized among the top global Propylene Oxide Manufacturers alongside companies like Dow, LyondellBasell, and BASF, Shell holds a strong market position through technological leadership and large-scale production capabilities. Achievements include operating multiple SM/PO plants with proven reliability, contributing to consistent supply in the Propylene Oxide market, and maintaining high safety and quality standards certified across international operations.

Shell's extensive experience in Propylene Oxide Production spans decades, with key facilities including the Moerdijk site in the Netherlands and the Jurong Island complex in Singapore (via joint venture ELLBA with BASF). These plants demonstrate successful case studies in integrated co-production of Propylene Oxide and Styrene Monomer, meeting growing demand in Asia and Europe while adapting to market expansions and regional supply needs.

Shell's expert teams focus on advancing Propylene Oxide technologies, emphasizing sustainability through lower-emission processes, bio-attributed feedstocks, and circular economy initiatives. Innovation efforts aim to enhance efficiency in Propylene Oxide Derivatives production while reducing environmental impact, aligning with global transitions toward greener chemical manufacturing.

Key Products Related to Propylene Oxide

Propylene Oxide

Styrene Monomer

Polyether Polyols

Propylene Glycols

Covestro AG is a world-leading German-based manufacturer of high-quality polymer materials, headquartered in Leverkusen. Established as an independent company in 2015 after spinning off from Bayer, Covestro specializes in high-tech polymers that drive innovation across industries. As a key player in the polyurethane value chain, the company excels in producing propylene oxide-based polyether polyols—essential precursors for polyurethane foams, elastomers, and coatings. These materials support applications in automotive lightweighting, energy-efficient construction, furniture comfort, and insulation. With global production sites across Europe, Asia, and North America, Covestro delivers sustainable, high-performance solutions to address megatrends like climate neutrality and circular economy.

Covestro maintains rigorous standards in sustainability and innovation, earning prestigious recognitions such as the Good Design Award for circular material innovations. The company advances climate neutrality goals through reduced CO₂ emissions, increased recycling rates, and adoption of bio-circular raw materials, including mass-balanced approaches for propylene oxide-derived products. It holds certifications for environmental excellence and actively contributes to cross-industry circular economy initiatives.

With a decade of independent operations built on decades of expertise, Covestro has delivered impactful projects worldwide. Examples include supplying propylene oxide-based polyether polyols for rigid foam insulation in energy-efficient buildings, flexible foams for automotive seating and bedding, and advanced polycarbonates for durable electronics and medical devices. Collaborations focus on sustainable applications, such as bio-based polyurethane dispersions and recycled materials in sportswear and security documents.

Covestro's diverse global team of scientists, engineers, and experts drives a holistic innovation culture, extending beyond R&D to digitalization, new business models, and open partnerships. Significant investments in global innovation centers support breakthroughs in alternative raw materials and process efficiencies, enabling propylene oxide-based solutions for a fully circular future.

Key Products

Propylene Oxide-Based Polyether Polyols (technical application support for polyurethane foam formulation)

Propylene Oxide and Ethylene Oxide Copolymer Polyols (customized solutions for flexible and rigid foams)

Polypropylene Ether Polyols (processing guidance for elastomers and coatings)

Thermoplastic Polyurethanes (material selection for durable consumer goods)

Polycarbonate Resins (design and performance optimization for automotive and electronics)

Huntsman Corporation is a publicly traded global manufacturer of differentiated and specialty chemicals, headquartered in The Woodlands, Texas. Founded in 1970, the company has grown into a major player with approximately $6 billion in annual revenues (2024), operating over 60 manufacturing, R&D, and operations facilities across 25 countries. Huntsman employs around 6,000 associates and focuses on innovative solutions in polyurethanes, advanced materials, and performance products. Historically involved in upstream intermediates, the company now emphasizes downstream applications, leveraging propylene oxide-derived chemistries to produce high-performance polyols and polyurethane systems essential for modern industries.

Huntsman is recognized as a leading global producer of MDI-based polyurethanes, with expertise in formulating differentiated products from propylene oxide-based polyether polyols. The company has achieved notable milestones in sustainability, including advancements in energy-saving insulation foams and lightweight materials, supported by a strong patent portfolio and commitment to UN Sustainable Development Goals. Its operations adhere to rigorous safety standards, earning accolades for reliable and innovative chemical manufacturing.

With over 50 years of expertise, Huntsman has extensive experience supplying propylene oxide-derived polyols and polyurethane systems for diverse applications, including energy-efficient building insulation, comfortable furniture and bedding foams, automotive lightweighting, protective coatings, adhesives, and elastomers in footwear. Case studies highlight successful deployments in aerospace, electronics, cold chain solutions, and electric vehicle battery materials.

Huntsman's dedicated team of approximately 6,000 associates worldwide drives continuous innovation through collaborative R&D and customer partnerships. The company invests in cutting-edge technologies to develop sustainable, high-performance solutions based on propylene oxide chemistries, addressing global challenges in energy transition, mobility, and comfort.

Key Products in Propylene Oxide-Related Chemistries

Polyether Polyols

Polyester Polyols

Propylene Carbonate

Thermoplastic Polyurethanes

MDI-Based Polyurethane Systems

INEOS Oxide, a division of the global INEOS Group, is Europe's largest producer of ethylene oxide and its derivatives, with a strong historical focus on propylene oxide and propylene-based chemicals. As a leading propylene oxide derivatives manufacturer, the company specializes in high-quality chemical intermediates derived from ethylene oxide and propylene oxide, serving industries such as automotive, coatings, personal care, pharmaceuticals, and agriculture. With world-scale assets across five key value chains—including ethylene oxide, propylene oxide derivatives, oxo-alcohols, acetate esters, and ethylidene norbornene—INEOS Oxide operates production facilities in Europe (Antwerp, Lavéra, Cologne) and the USA (Plaquemine, Bayport), delivering approximately 4 million tonnes annually. In 2025, the company ceased direct propylene oxide and propylene glycols production at its Cologne site due to market challenges, shifting emphasis toward ethylene oxide leadership and sustainable derivatives.

INEOS Oxide holds globally recognized certifications, including ISO 9001 for quality management, EXCiPACT for pharmaceutical excipients (e.g., ethanolamines), and RSB/ISCC for bio-attributed products. Key achievements include major expansions in ethylidene norbornene capacity, investments in deep-sea terminals, and the 2024 acquisition of a U.S. ethylene oxide and glycol ethers facility, enhancing global supply reliability.

With roots tracing back to 1966 and integration into INEOS since 1998, the company has decades of expertise in oxide production and derivatives manufacturing. Notable cases include successful integrations of acquired assets (e.g., Dow's ethanolamines in 2001, Innovene's propylene oxide-related plants in 2005) and co-location partnerships attracting €430 million in investments at Antwerp.

Employing around 1,200 professionals worldwide, INEOS Oxide fosters innovation through commitments to sustainability, such as launching bio-attributed ethylene oxide and expanding low-toxicity propylene glycol ethers for coatings and cleaners.

Key Products

Propylene Oxide Derivatives

Propylene Glycols

Propylene Glycol Ethers (P-Series)

Glycol Ethers

Ethoxylates

Alkoxylates

SKC Co., Ltd., founded in 1976 in South Korea, is a diversified specialty materials company with a significant historical footprint in the chemical sector, particularly as a propylene oxide manufacturer through strategic joint ventures. Since entering the propylene oxide (PO) business in 1991 by localizing production in Korea, SKC has leveraged partnerships to build integrated operations. Notably, in 2019, SKC spun off its chemical division to form SK picglobal, a joint venture with Kuwait's Petrochemical Industries Company (PIC), where SKC holds the controlling stake. SK picglobal operates advanced propylene oxide production facilities in Ulsan, focusing on eco-friendly processes and downstream derivatives essential for polyurethane applications in automotive, construction, and furniture industries.

SKC pioneered the world's first commercial-scale Hydrogen Peroxide to Propylene Oxide (HPPO) process in 2008, a breakthrough eco-friendly technology that avoids chlorinated by-products and co-produces none, setting a global standard among propylene oxide manufacturers. This innovation, supported by collaborations with Evonik for hydrogen peroxide supply, expanded production capacity to approximately 300,000 tons per year. Recognized in industry rankings as a top propylene oxide producer, SKC maintains high standards in sustainable manufacturing.

With over 30 years in propylene oxide production, SKC has supplied reliable, high-purity materials to global polyurethane chains. Through SK picglobal, the company supports diverse applications, including flexible foams for automotive seating and rigid insulation for construction, demonstrating proven scalability and supply chain reliability.

SKC's experienced R&D teams drive advancements in propylene oxide manufacturing, emphasizing sustainability and process efficiency. Ongoing innovations in HPPO technology and joint venture collaborations reinforce its leadership in green chemical solutions.

Key Products

Propylene Oxide (PO)

Propylene Glycol (PG)

Polyether Polyols

Styrene Monomer (SM)

Repsol is a Spanish multinational energy and petrochemical company headquartered in Madrid, operating globally across upstream, downstream, and chemicals segments. In the chemicals division (Repsol Materials), the company excels as a prominent propylene oxide manufacturer, utilizing proprietary PO/SM technology for co-production of propylene oxide and styrene monomer. Repsol produces a range of propylene oxide derivatives, including polyether polyols and propylene glycols, from facilities in Spain, supporting industries like polyurethanes, foams, and specialty chemicals.

Repsol maintains high industry standards with integrated production of base petrochemicals (ethylene, propylene) and derivatives. Key achievements include decades of reliable propylene oxide production, technology licensing for PO/SM plants (e.g., capacities up to 200,000 tonnes/year propylene oxide), and innovations like CO2-based polycarbonate polyols that partially substitute traditional propylene oxide for sustainability. The company has earned recognition among top global propylene oxide manufacturers for efficiency and environmental advancements.

With experience dating back to the 1970s, when Repsol built its first PO/SM plant in Puertollano, the company operates major sites in Tarragona and elsewhere. Proven cases include successful maintenance and recovery of propylene oxide lines, international technology transfers to China for integrated propylene oxide and polyether polyols production, and strategic partnerships that expand global reach in the propylene oxide manufacturers ecosystem.

Repsol's expert team drives R&D in propylene oxide derivatives and sustainable processes. Through strategic partnerships and innovation hubs, the company advances PO/SM technology, circular solutions, and low-carbon alternatives in polyether polyols production, reinforcing its leadership among propylene oxide manufacturers.

Key Products

Propylene Oxide

Polyether Polyols

Propylene Glycols

Styrene Monomer

Westlake Corporation (NYSE: WLK) is a Fortune 500 global diversified industrial company headquartered in Houston, Texas. Founded in 1986 by T.T. Chao with the acquisition of a polyethylene plant in Lake Charles, Louisiana, Westlake has grown into a leading manufacturer and supplier of performance materials, essential chemicals, and housing/infrastructure products. Serving industries such as construction, packaging, healthcare, automotive, and consumer goods, the company operates worldwide with approximately 16,000 employees and reported net sales of $12.1 billion in 2024. Its operations span two core segments: Performance & Essential Materials (focused on olefins, polyethylene, vinyl chemicals, and epoxies) and Housing & Infrastructure Products (including PVC pipe, fittings, compounds, and building materials).

Westlake holds strong industry recognition, including consistent placement on the Fortune 500 list and multiple safety excellence awards from organizations like CSX. Its epoxy business has earned EcoVadis Platinum and Gold ratings, placing it among the top performers in sustainability within the chemical sector. The company has also received accolades for operational safety and environmental stewardship.

With nearly four decades of expertise, Westlake has expanded through strategic acquisitions, such as Hexion's global epoxy business (2022), Boral's North American building products (2021), and LASCO Fittings. These moves have strengthened its portfolio in essential chemical building blocks and downstream applications, supporting reliable supply chains for global customers in essential everyday products.

Westlake's dedicated global team drives innovation focused on sustainability and responsible chemistry. The company achieved its 2030 goal of 20% reduction in Scope 1 and 2 CO₂e emissions per ton of production ahead of schedule in 2024, with new commitments for further reductions. Initiatives include lower-carbon GreenVin PVC, recycled plastic materials, and investments in circular economy technologies, ensuring durable, safe, and environmentally responsible solutions.

Key Products

Ethylene

Styrene Monomer

Polyethylene

Polyvinyl Chloride (PVC) Resin

The U.S. propylene oxide industry is characterized by a relatively small number of highly integrated producers, significant capital intensity, and an increasing emphasis on sustainable production. As of 2026, competitive advantage lies in a combination of production scale, advanced technology adoption, and strong downstream integration, particularly into polyurethane and specialty chemical markets.

Vertical Integration: Leading manufacturers benefit from integrated supply chains that combine propylene feedstock access, efficient production, and direct downstream usage. This integration drives both cost advantages and supply reliability.

Technology Leadership: Adoption of modern production routes—especially HPPO (Hydrogen Peroxide to Propylene Oxide)—continues to differentiate manufacturers on efficiency, environmental performance, and long-term operational cost.

Market Positioning: Companies with diversified downstream portfolios (e.g., polyurethanes and propylene glycol derivatives) demonstrate stronger resilience to raw material price swings and demand fluctuations.

Sustainability and Emissions Reduction: Environmental performance is an increasingly important factor for customers, regulators, and investors. Producers that prioritize low-emission technologies and waste reduction are gaining market preference.

Stable Domestic Demand: End-use sectors such as construction insulation, automotive, and consumer goods continue to support steady propylene oxide demand, making the U.S. market one of the world’s most reliable.

Operational Resilience: Supply chain disruptions and geopolitical pressures reinforce the value of domestic production capability and diversified supplier relationships.

Looking forward, the U.S. propylene oxide market is expected to maintain moderate growth, underpinned by ongoing demand in core end-use industries and continued investment in cleaner production technologies. Manufacturers that combine technology leadership, sustainable operations, and deep integration with downstream markets are best positioned for long-term success.

In summary, propylene oxide remains a strategic chemical intermediate in the U.S., central to everything from polyurethane foams to specialty chemicals. The competitive landscape in 2026 is shaped by a relatively small set of manufacturers that distinguish themselves through scale, efficiency, technology adoption, and integrated market positioning.

For procurement professionals, supply chain managers, and industry investors seeking reliable upstream partners, understanding these structural dynamics is key to making informed sourcing decisions.

If your organization requires trusted propylene oxide supply, expert insights into U.S. chemical manufacturers, or support navigating complex procurement decisions, High Mountain Chemicals is positioned to help.