The global chloroacetic acid market reached a valuation of USD 1.4 billion in 2024 and is projected to expand to USD 2.6 billion by 2037, representing a compound annual growth rate (CAGR) of 4.9% throughout the forecast period from 2025 to 2037. This substantial market expansion reflects the chemical's critical role across multiple industrial sectors, positioning chloroacetic acid as an indispensable intermediate in modern chemical manufacturing processes.

Market analysts present varying growth projections based on different methodological approaches. Alternative forecasts estimate the global chloroacetic acid market at USD 1.405 billion in 2025, with projections reaching USD 1.71 billion by 2034 at a CAGR of 2.3%, while more aggressive estimates value the market at USD 2,238.21 million in 2024, expecting growth to USD 3,570.64 million by 2031 with a CAGR of 6.9%. These variations underscore the dynamic nature of the chloroacetic acid industry and its sensitivity to regional industrial development patterns.

The Asia Pacific region demonstrates commanding market leadership, projected to control 56.4% of the global chloroacetic acid market share by 2037. This regional dominance stems from concentrated manufacturing capabilities in China and India, where robust chemical production infrastructure, competitive labor costs, and proximity to raw material sources create favorable conditions for chloroacetic acid synthesis and derivative production.

Asia-Pacific's extensive industrial base, particularly in China and India, positions these nations as leading producers and consumers of chloroacetic acid, with growth driven by expanding manufacturing sectors in chemicals, pharmaceuticals, and agrochemicals. The region's agricultural modernization initiatives, pharmaceutical industry expansion, and increasing specialty chemical production capacities collectively fuel chloroacetic acid consumption across diverse application segments.

North American and European markets maintain significant positions within the global landscape, though experiencing comparatively slower growth trajectories. These mature markets demonstrate steady demand patterns driven primarily by pharmaceutical innovation, specialty chemical development, and stringent quality requirements for high-purity monochloroacetic acid (MCAA) derivatives used in regulated industries.

The healthcare segment commands a substantial 41.6% market share during the forecast period, serving as an essential intermediate in synthesizing various pharmaceuticals, including anticancer drugs and local anesthetics. The escalating prevalence of chronic diseases globally, combined with advancing personalized medicine approaches, intensifies pharmaceutical demand for chloroacetic acid derivatives used in active pharmaceutical ingredient (API) production.

Carboxymethylcellulose (CMC) production represents chloroacetic acid's largest application segment, with MCA's extensive use in manufacturing CMC, herbicides, and surfactants. CMC functions as a critical thickening and stabilizing agent across food processing, pharmaceutical formulations, cosmetic products, and industrial detergent applications, creating sustained demand for monochloroacetic acid feedstock.

The agrochemical sector provides another substantial growth driver for chloroacetic acid consumption. MCA's role in herbicide production supports the expanding agriculture sector, with rising global population, increased agricultural activity, and demand for processed foods contributing to MCA consumption growth. Modern farming practices increasingly rely on effective herbicide formulations, many of which utilize chloroacetic acid derivatives as key intermediates.

Emerging economies in Latin America, Southeast Asia, and parts of Africa present significant expansion opportunities for chloroacetic acid market participants. The collaboration between Nouryon and Atul Ltd established a joint venture in Gujarat, India, to produce MCA, specifically targeting rising demand in agriculture, personal care, and pharmaceutical markets. Such strategic investments reflect industry recognition of high-growth potential in developing regions where industrial chemical consumption accelerates alongside economic development.

Manufacturing capacity expansion in emerging markets addresses both local consumption growth and export opportunities to established markets. The establishment of regional production facilities reduces logistics costs, minimizes supply chain vulnerabilities, and enables manufacturers to respond more effectively to local customer requirements while maintaining competitive pricing structures in price-sensitive markets.

The chloroacetic acid market's robust growth trajectory through 2037 positions the chemical as a cornerstone ingredient in global chemical manufacturing, with sustained demand across pharmaceutical, agrochemical, food processing, and specialty chemical industries driving market expansion across both developed and emerging economies.

Chloroacetic acid is prepared industrially by two routes, with the predominant method involving chlorination of acetic acid using acetic anhydride as a catalyst. Modern chemical manufacturers favor the chlorination approach due to its economic advantages and operational flexibility, despite challenges associated with byproduct formation and purification requirements.

The acetic acid chlorination method involves directly chlorinating acetic acid with chlorine gas in the presence of catalysts such as iodine, phosphorus, sulfur, or halides of phosphorus and sulfur. The fundamental chemical reaction proceeds according to the equation: CH₃COOH + Cl₂ → ClCH₂COOH + HCl, yielding monochloroacetic acid and hydrochloric acid as a byproduct.

China's production utilizes acetic acid chlorination with approximately 3.5% sulfur powder (by weight of glacial acetic acid) as the catalyst, with preheating to temperatures exceeding 90°C before introducing chlorine gas. Process control maintains the main reaction pot at 98±2°C while a secondary auxiliary pot operates at 85-90°C, ensuring optimal conversion efficiency while minimizing unwanted side reactions.

The yield of chloroacetic acid through acetic acid chlorination can reach 92%, making this route economically attractive for large-scale manufacturing operations. Raw material consumption typically requires glacial acetic acid (98%) at 730kg/ton, chlorine at 860kg/ton, and sulfur at 26kg/ton for industrial chloroacetic acid production.

The catalytic mechanism employs acetic anhydride or acetyl chloride to enhance reaction kinetics and selectivity. This synthesis produces a gaseous stream of crude hydrochloric acid as a byproduct, which contains chlorine and acetyl chloride values requiring purification through compression, cooling sequences, and recycling of other products back into the chlorination reactor.

The chlorination route suffers from the production of dichloroacetic acid and trichloroacetic acid as impurities, which are difficult to separate. These over-chlorinated byproducts form when chlorine continues reacting with monochloroacetic acid molecules, particularly under conditions of excess chlorine or extended reaction times.

A more significant purification method involves catalytic hydrodechlorination of undesired byproducts, where di- and trichloroacetic acids can be dechlorinated through catalytic hydrogenation at high temperature, typically using palladium on a carrier such as carbon. This additional processing step adds complexity and cost to the overall production process but enables manufacturers to achieve pharmaceutical-grade purity specifications.

Alternatively, mother liquor consisting of acetic acid, chloroacetic acid, and di- and trichloroacetic acids can be further chlorinated under ideal conditions to yield the useful trichloroacetic acid, converting what would otherwise be waste streams into valuable specialty chemical products.

Chloroacetic acid can be produced using a continuous process in which equal amounts of trichloroethylene and 75% sulfuric acid are reacted at 130-140°C, and upon complete conversion of trichloroethylene, the reaction mixture contains about 50% chloroacetic acid and 1–2% water. This hydrolysis is conducted at 130–140°C in a concentrated solution of at least 75% sulfuric acid.

This method produces a highly pure product, unlike the halogenation route, however, the significant quantities of HCl released have led to the increased popularity of the halogenation route. The trichloroethylene hydration method can achieve chloroacetic acid yields reaching 90%, but more hydrochloric acid is generated as a byproduct.

This method yields 1000 kg of finished product and 700–750 kg of HCl gas as a byproduct from 1500–1850 kg of trichloroethylene and 600 kg of H₂SO₄ (95%). The substantial hydrochloric acid generation requires dedicated capture, purification, and utilization infrastructure, adding to capital and operational costs.

The trichloroethylene method produces highly pure chloroacetic acid that is free of di- or trichloroacetic acid, however, this method is no longer in use due to the high cost of trichloroethylene and the significant amount of HCl generated as a byproduct. The shift away from this route reflects both economic considerations and environmental management challenges associated with large-volume HCl disposal or recovery.

In North America, acetic acid chloride methods predominate, while Western Europe traditionally favored trichloroethylene water-based processes, though these regional preferences have evolved with changing feedstock economics and environmental regulations. The global trend increasingly favors chlorination approaches that minimize sulfuric acid consumption and reduce corrosive byproduct streams.

Approximately 420,000 tonnes of chloroacetic acid are produced globally per year, with production capacity concentrated in regions offering competitive access to acetic acid, chlorine, and energy resources. Manufacturing economics favor integrated chemical complexes where chlorine byproducts from chlor-alkali operations can be directly consumed in chloroacetic acid synthesis, minimizing transportation and storage costs for this hazardous feedstock.

Recent patent innovations focus on improving HCl recovery and recycling, reducing catalyst consumption, and enhancing selectivity toward monochloroacetic acid while suppressing over-chlorination reactions. These process improvements contribute to better atom economy, reduced waste generation, and improved profitability for chloroacetic acid manufacturers operating in increasingly competitive global markets.

Carboxymethyl cellulose (CMC) or cellulose gum is a cellulose derivative with carboxymethyl groups (-CH₂-COOH) bound to some of the hydroxyl groups of the glucopyranose monomers that make up the cellulose backbone, synthesized by the alkali-catalyzed reaction of cellulose with chloroacetic acid. This chemical transformation represents the single largest industrial application for monochloroacetic acid, consuming substantial volumes of the chemical worldwide to produce one of the most versatile water-soluble polymers in commercial use.

The production of CMC comprises two steps, alkalization and carboxymethylation, using chloroacetic acid serially. The alkalization step employs sodium hydroxide to swell the cellulose structure and convert hydroxyl groups into more reactive alkoxide forms, while the subsequent carboxymethylation introduces carboxymethyl functional groups through nucleophilic substitution reactions with chloroacetic acid or sodium chloroacetate.

Crude cellulose fractionated from cornstalk, after leaching, can be used as the raw material for the synthesis of sodium carboxymethyl cellulose (CMC) by reacting with the cellulose with NaOH and chloroacetic acid at 75°C for 1.5 h. To obtain CMC with high water solubility, the molar ratio of NaOH to chloroacetic acid should be appropriately controlled, with synthesis at the molar ratio of NaOH/ClCH₂COOH ≈1.6–1.64 under present reaction conditions.

Manufacturing processes employ organic solvents to facilitate uniform reactions and prevent gelation during synthesis. The slurry method can not only produce high purity sodium carboxymethyl cellulose, but also prepare sodium carboxymethyl cellulose with high degree of substitution and uniform substitution, with cotton pulp ground into powder sent to a vertical alkalization machine with isopropanol, adding sodium hydroxide solution while stirring at alkalization temperature of about 20°C.

After alkalization, the material is transported to the vertical etherification machine by pump, adding the isopropanol solution of chloroacetic acid, with the etherification temperature at about 65°C. Process parameters including alkalization concentration, alkalization time, amount of etherification agent, and etherification time can be adjusted according to specific product use and quality requirements.

One of the critical characteristics of sodium CMC was a degree of substitution (DS), with the highest value of the degree of substitution acquired in a mixture solvent of isopropanol:ethanol (50:50) at 0.91 compared with a solvent mixture of isopropanol:isobutanol (30:70). The degree of substitution directly determines CMC solubility, viscosity characteristics, and performance in end-use applications.

DS values between 0.0 and 0.4 mean that CMC is insoluble but swellable, and above this range mean that the CMC is completely water-soluble. Commercial CMC products typically exhibit DS values ranging from 0.4 to 1.4, with specific applications requiring particular substitution ranges to achieve desired functional properties in formulated products.

Appropriate and optimized molar ratios of alkali (NaOH) to chloroacetate yields a higher degree of substitution, which usually ranges from 0.5 to 1.4, with CMC having DS value greater than 0.4 exhibiting greater solubility in water under homogenous conditions. Obtaining higher DS (>1.5) values would be a challenging issue because increase in the electrostatic repulsion between the CMC modified chains and the approaching sodium chloroacetate will avert its substitution.

The molecular weight of synthesized CMC significantly influences its rheological properties and application performance. Weight average molecular weight (Mw) of CMC greatly influences the intrinsic viscosity, viscoelasticity and mechanical properties, with higher molecular weight grades producing more viscous solutions suitable for applications requiring substantial thickening effects.

CMC is used for a viscosity modifier or thickener and to stabilize emulsions in various products, including ice cream, mayonnaise, and beverages. The food industry represents one of the largest consumption sectors for pharmaceutical-grade and food-grade CMC, with the additive registered as E466 or E469 when enzymatically hydrolyzed for European markets.

Carboxymethylcellulose is now one of the most essential food additives, widely used in high quality ice cream (to resist melting), sweets, biscuits, cakes, cookies, candies, juices, liquid beverages, dairy products and meat products, frozen foods, instant pastas, canned and fruit compotes. Since CMC is a low-calorie polysaccharide, it is used in diet and low-calorie foods such as diet breads, diet drinks and diet sauces.

CMC's functionality in food applications extends beyond simple thickening to include moisture retention, texture modification, and shelf-life extension. One of the important applications of CMC is the stability and protection of proteins, especially bran proteins, enabling manufacturers to maintain product quality throughout distribution and storage.

Carboxymethyl cellulose (CMC) is defined as an organic polysaccharide compound derived from cellulose through an alkali-catalyzed reaction with chloroacetic acid, commonly used as an ingredient in film-coated tablets, ophthalmic drops, oral suspensions, and as a stabilizer in injectable drugs. The pharmaceutical industry demands ultra-high purity CMC grades free from residual chloroacetic acid and other impurities that might compromise drug safety or efficacy.

It used to be marketed under the name Tylose, a registered trademark, with the sodium salt used pharmaceutically as an artificial lubricant for the eye in a 0.25% solution in water under the brand name Theratears. An injectable form has been investigated for use as a soft tissue filler, and it is also used as a wound dressing under multiple brand names.

The biocompatibility and non-toxic nature of CMC make it particularly valuable for biomedical applications. The biocompatibility and rigidity of cellulose allow this material to be an important polymeric matrix in the study of drug delivery, with CMC obtained by hydrating cellulose in an alkaline medium, followed by a reaction with chloroacetic acid, providing greater viscosity and solubility due to the formation of ionizable side groups.

CMC aids in pigment suspension and dispersion, binding other ingredients for even distribution, and when combined with Fatty Acid Ethanolamine or 2,2'-Iminodiethanol in a hair product, can form a thin film around the hair. Personal care product formulations utilize CMC's film-forming and thickening properties to improve product texture, stability, and performance on skin and hair.

As a thickening agent, CMC can increase the viscosity of drilling fluids and form a network structure in the mud, thereby enhancing their suspension capacity and effectively protecting the wellbore and managing the penetration and loss of moisture in the drilling fluid. Ultra-high viscosity Sodium Carboxymethyl Cellulose can be used in fracturing fluids, primarily to carry fillers into oil wells.

In oil drilling, CMC can be used to protect oil wells as mud stabilizer and water retaining agent, with dosage of each oil well at 2-3t for shallow wells and 5-6t for deep wells. The petroleum industry's substantial CMC consumption for drilling operations creates consistent demand for monochloroacetic acid feedstock.

The detergent and textile industries represent additional significant CMC markets. The detergent industry is the largest consumer of CMC, with technical grade CMC compositions most often used for soaps and detergents, acting as an inhibitor of the redeposition of grease in the fabric after it has been removed by the detergent. In the textile industry, CMC serves as a sizing agent, printing and dyeing pulp thickening agent, and textile printing and stiff finishing agent, with its dosage as a stiff finishing agent exceeding 95%.

The dominant position of CMC production as the primary application for chloroacetic acid ensures that trends in CMC markets directly influence monochloroacetic acid demand, pricing, and production capacity planning across the global chemical manufacturing industry.

The agrochemical sector represents a critical application segment for chloroacetic acid, consuming substantial volumes as an intermediate in herbicide synthesis. Another industry that uses monochloroacetic acid is the agrochemicals industry, where they are the main constituents of plant protection products, which are essential for the cultivation of plants such as herbicides or insecticides. This demand stems from chloroacetic acid's role in producing some of agriculture's most widely deployed weed control chemicals.

2,4-D is a member of the phenoxy family of herbicides, manufactured from chloroacetic acid and 2,4-dichlorophenol, which is itself produced by chlorination of phenol. Alternatively, it is produced by the chlorination of phenoxyacetic acid. The synthesis process involves nucleophilic substitution where the phenoxide anion attacks chloroacetic acid, displacing chloride and forming the characteristic phenoxyacetic acid structure central to this herbicide class.

2,4-Dichlorophenoxyacetic acid—"2,4-D" to millions of farmers—is one of the most widely used broadleaf herbicides in the world, with its preparation from 2,4-dichlorophenol and chloroacetic acid reported by R. Pokorny in 1941, and developed as a major herbicide during World War II. The historical significance of 2,4-D extends beyond agricultural productivity to represent one of the earliest successful synthetic herbicides, fundamentally transforming agricultural weed control practices globally.

In the USA, 2,4-D is one of the 10 most commonly used conventional active ingredients of pesticide used in the agricultural sector, with use estimates from 2001 to 2007 ranging from 24 to millions of pounds annually. This sustained high-volume consumption ensures consistent demand for chloroacetic acid feedstock, with production economics favoring integrated manufacturing facilities that can supply both chloroacetic acid and dichlorophenol components.

2,4-D is a synthetic auxin that induces uncontrolled growth and eventually death in susceptible plants, absorbed through the leaves and translocated to the meristems of the plant, with uncontrolled, unsustainable growth ensuing, causing stem curl-over, leaf withering, and eventual plant death. This mechanism provides selective control of broadleaf weeds in monocot crops including cereal grains, making it particularly valuable for wheat, corn, rice, and other grass family crops.

2,4-Dichlorophenoxyacetic acid (2,4-D) was the first synthetic herbicide to be commercially developed and has commonly been used as a broadleaf herbicide for over 60 years, a selective herbicide that kills dicots without affecting monocots and mimics natural auxin at the molecular level. Physiological responses of dicots sensitive to auxinic herbicides include abnormal growth, senescence, and plant death.

The pesticide allows not just grasses but also fruits and vegetables to flourish by attacking both the roots and leaves of weeds, making the unwanted plant's cells grow out of control—sort of like inducing cancer in the plant to kill it or drastically slow its spread, used widely in agriculture in soybean, corn, sugarcane, and wheat fields. The compound's broad crop compatibility and effective weed suppression contribute to its enduring market position despite regulatory scrutiny in various jurisdictions.

In the 2000s, Dow AgroSciences developed a new choline salt version of 2,4-D (2,4-D choline) that Dow included in its "Enlist Duo" herbicide along with glyphosate and an agent that reduces drift, with the choline salt form of 2,4-D being less volatile than 2,4-D. In October 2014, the US EPA registered Enlist Duo, an herbicide containing the less volatile 2,4-D choline salt, glyphosate, and an antidrift agent, for use in six states: Illinois, Indiana, Iowa, Ohio, South Dakota, and Wisconsin.

As of April 2014, genetically modified maize and soybeans resistant to 2,4-D and glyphosate have been approved in Canada, and in September 2014, the USDA also approved Dow's maize and soybeans. The development of herbicide-resistant crop varieties enables higher application rates and more flexible weed management strategies, potentially increasing per-acre consumption of 2,4-D and consequently chloroacetic acid derivative demand.

Originally, plants genetically engineered to resist Roundup were sprayed with that herbicide alone, but when the weeds it was intended to kill also developed resistance, 2,4-D was added to make the mix more effective. This herbicide resistance management strategy addresses one of modern agriculture's most significant challenges—weed populations developing genetic resistance to single-mode-of-action herbicides through repeated exposure over multiple growing seasons.

The phenoxy herbicide family extends beyond 2,4-D to include multiple chloroacetic acid-derived compounds. With the use of MCAA, the following substances are produced, including MCPA (2-Methyl-4-chlorophenoxyacetic acid), which provides similar selective broadleaf weed control with different volatility and environmental persistence characteristics compared to 2,4-D.

Academic and industrial laboratories synthesized several synthetic auxins including 1-NAA, 2,4-D, and MCPA as early as the 1940s, with synthetic auxin herbicides opening a new era of weed control in modern crop production due to their selective action, and preferential control of dicot weeds in cereal crops. This entire class of synthetic auxin herbicides relies fundamentally on chloroacetic acid as a key building block, linking agricultural productivity directly to chloroacetic acid manufacturing capacity.

The agrochemical applications of chloroacetic acid derivatives contribute substantially to global food security by enabling effective weed management with reduced labor requirements. Modern agriculture's reliance on chemical weed control, particularly in large-scale mechanized farming operations, creates structural demand for herbicide active ingredients derived from chloroacetic acid.

Herbicides are agrochemicals used to control the growth of undesired weeds, and aim to significantly increase crop productivity, with most herbicides being small molecules that normally do not cause intrinsic toxicities but inhibit specific molecular target sites within critical plant biochemical and/or physiological pathways. The economic value of preventing crop yield losses to weed competition far exceeds herbicide application costs in most commercial farming systems, sustaining consistent market demand despite fluctuating commodity prices.

The expanding global population, increasing meat consumption requiring additional grain production for livestock feed, and climate change impacts on agricultural yields collectively ensure continued growth in agrochemical consumption, particularly in developing nations modernizing agricultural practices. This demographic and agricultural modernization trajectory supports long-term chloroacetic acid demand growth from the herbicide manufacturing segment, positioning agrochemicals as a stable and expanding market for chloroacetic acid producers through 2037 and beyond.

Chloroacetic acid serves as a versatile building block for producing numerous specialty chemicals that find applications across cosmetics, pharmaceuticals, surfactant manufacturing, and industrial chemical processing. These derivatives leverage chloroacetic acid's reactive chloromethyl group, enabling nucleophilic substitution reactions with diverse chemical reagents to generate high-value specialty products.

Thioglycolic acid production involves the substitution of a chlorine atom in chloroacetic acid with a sulfhydryl (thiol) group from hydrogen sulfide, resulting in the formation of thioglycolic acid. Sodium hydrosulfide and chloroacetic acid are prepared under the action of hydrogen sulfide and nitrogen, with the reaction formula: NaSH+ClHCH2COOH→HSCH2COOH+NaCl.

Thioglycolic acid (TGA) is the organic compound HSCH2CO2H, often called mercaptoacetic acid (MAA), containing both a thiol (mercaptan) and carboxylic acid functional groups, appearing as a colorless liquid with a strongly unpleasant odor. In its raw form, it appears as a colorless liquid, with purification steps carried out to obtain the final product.

Alternative synthetic routes provide manufacturing flexibility. Monochloroacetic acid reacts with sodium sulfide and sulfur to generate dithiodiacetic acid, which is then reduced with zinc and acid; or thiocarbamate reacts with monochloroacetic acid, and the product is obtained by hydrolysis; monochloroacetic acid and thiourea reaction produces isothiourea acetic acid, which is then converted into precipitation with barium hydroxide, and then acidified with sulfuric acid to prepare an aqueous solution of thioglycolic acid, which can be evaporated to obtain a 60%-70% solution with a yield of over 70%.

The annual United States production of thioglycolic acid was reported to be in the range of 10 to 50 million pounds for 2005, reflecting substantial industrial demand for this specialty chemical across multiple application sectors.

Thioglycolic acid is a chemical compound commonly used in cosmetics, particularly in hair removal products, with its primary function to break down the protein structure of hair, making it more pliable and easier to remove. Thioglycolic acid is a key component in depilatory creams and lotions, where it works by disrupting the disulfide bonds in the keratin protein of hair, weakening the hair shaft, allowing for mechanical removal or its dissolution.

TGA is used as a chemical depilatory and is still used as such, especially in salt forms, including calcium thioglycolate and sodium thioglycolate. TGA is the precursor to ammonium thioglycolate, which is used for permanents, with TGA and its derivatives breaking the disulfide bonds in the cortex of hair, reforming these broken bonds in giving hair a "perm".

Thioglycolic acid, ammonium thioglycolate, and glyceryl thioglycolate are predominantly used in permanent wave and hair straightening products. Thioglycolic acid and ammonium thioglycolate concentrations in these products range from 7% to 19%, while glyceryl thioglycolate concentrations of 20% have been reported.

Permanent wave products containing ammonium thioglycolate that are applied to the hair without heat may be expected to remain on the hair and scalp for as long as 10 to 40 minutes; products applied with heat usually contain thioglycolates other than the ammonium salt and are generally processed in 30 minutes but may remain on the head for up to 1 hour.

Thioglycolic acid acts as a stabilizer in PVC, functioning to prevent degradation of polyvinyl chloride during high-temperature processing operations. Thioglycolic acid is used to make epoxy resin, catalyst of bisphenol A, and can also be used in the processing of PVC water pipes, water pumps and other products, food packaging, equipment piping in a food processing plant.

Noncosmetic uses of thioglycolic acid include use in the manufacture of pharmaceuticals and thioglycolates, as a vinyl stabilizer, and as an analytical reagent for iron, molybdenum, silver, and tin. Thioglycolic acid is also a sensitive reagent for the determination of iron, molybdenum, lead, tin, etc..

Thioglycolic acid is an intermediate in the production of thiomethoprol (caputril), biotin, thiozinc acid, sodium dithiosuccinate and other pharmaceuticals, and is also an intermediate in the synthesis of cysteine, hormonal agent, and industrial disinfectant. Thioglycolic acid is used as antioxidant and stabilizer in pharmaceuticals to enhance the stability of the main drug and prolong the validity period of pharmaceutical preparations.

Betaine surfactants represent another major specialty chemical family derived from chloroacetic acid chemistry. Despite the name, the Cocamidopropyl betaine molecule is not synthesized from betaine, with a common way of producing Cocamidopropyl betaine to combine fatty acids derived from coconut or palm kernel oil (mainly lauric acid, or its methyl ester) with a colorless liquid called dimethylaminopropylamine (DMAPA), with the reactiveness of the primary amine in DMAPA leading to forming of amide in the first step, and next, the chloroacetic acid reacts with the unaltered tertiary amine to form a quaternary ammonium center.

The amide undergoes quaternization with chloroacetic acid, resulting in the formation of cocamidopropyl betaine, according to the reaction: CH₃(CH₂)₁₀CONHCH₂CH₂CH₂N(CH₃)₂ + ClCH₂COOH + NaOH → Cocamidopropyl Betaine + byproducts. This synthesis results in a zwitterionic compound with both a quaternary ammonium group and a carboxylate group, which contributes to its surfactant properties.

The production process for cocamidopropyl betaine involves performing complete reaction of 137.1 kg of liquid caustic soda with 32% content and 89.1 kg of chloroacetic acid with 99.5% content, wherein the molar ratio is 1.05:1, adding 446 kg of measured process water, with PH value qualified in range of 4-5. Then add equimolar (monochloroacetic acid : hydrogenated coco amido propyl tertiary amine=1:1) hydrogenated coco amido propyl tertiary amine 272.1 kilograms, open steam valve and heated, when reaction temperature reaches 85-95°C, close steam valve stops heating, and the reaction time in 3-4 hours.

CAPB is available as a viscous pale yellow solution and it is used as a surfactant in personal care products and animal husbandry. Cocamidopropyl betaine to a significant degree has replaced cocamide DEA, offering improved safety profiles and regulatory compliance compared to earlier-generation surfactants.

The impurities AA (amidoamine) and DMAPA (dimethylaminopropylamine) are most critical, as they have been shown to be responsible for skin sensitization reactions, with these by-products avoided by a moderate excess chloroacetate and the exact adjustment of pH value during betainization reaction accompanied by regular analytical control.

During the process of synthesis, two main impurities, amidoamine (AA) and DMAPA were proved to be the origin for skin sensitization reactions, which make CAPB become an allergen, with these impurities prevented by using a modest excess of chloroacetate and precisely adjusting the pH value throughout the betainization reaction, together with frequent analytical monitoring.

Sodium chloroacetate (SCA) plays a crucial role in the final step of alkyl betaine synthesis, with this reactant prone to hydrolysis, which results in the formation of sodium glycolate and hydrochloric acid, which will protonate the amine reactant and thus limit its conversion to betaine. SCA is often contaminated with a small amount of dichloroacetic acid (DCA), a suspected carcinogen, thus it is necessary to use ultrahigh-purity SCA to minimize the amount of DCA in the final product.

Cocamidopropyl Betaine (CAB) is a mild amphoteric surfactant, irreplaceable in modern cosmetic formulas, used as a primary and secondary surfactant in DIY cosmetic products, including shampoos, shower lotions, bath foams, face washes, and more, with CAB also found in makeup removers, shaving creams, contact lens solutions, household spray cleaners, and disinfecting wipes.

Lauramidopropyl Betaine is typically produced by reacting lauric acid, derived from coconut oil, with dimethylaminopropylamine and chloroacetic acid, forming the amphoteric surfactant, Lauramidopropyl Betaine. Lauramidopropyl Betaine is widely valued for its foaming and cleansing properties, making it suitable for shampoos, body washes, and facial cleansers, acting as a mild and gentle ingredient, helping to remove dirt and excess oils from the skin and hair without causing irritation.

Most betaine surfactants use an oleochemical hydrophobe precursor obtained from tropical oils as the bio-based component, with even though sarcosine and betaine being naturally occurring molecules, they are mostly synthesized on a large scale by combining chloroacetic acid with N-methylamine for sarcosine and with petrochemical-based trimethylamine for betaine.

Alkyl betaines have good detergency and high foaming capacity, with most of them significantly soluble in water, attractive as foaming agents because their foam is relatively resistant to hard water. The maximum concentration of alkyl betaines in either leave-on or rinse-off products is less than 10%, with the Cosmetic Ingredient Review (CIR) Expert Panel confirming that alkyl betaines are safe in their current practice of use and concentration.

The diversity of specialty chemicals accessible through chloroacetic acid chemistry demonstrates the compound's fundamental importance in producing high-value derivatives for cosmetics, personal care, pharmaceuticals, and industrial applications. Manufacturing facilities producing these derivatives require consistent chloroacetic acid supply meeting stringent quality specifications, ensuring continued demand growth as specialty chemical markets expand globally.

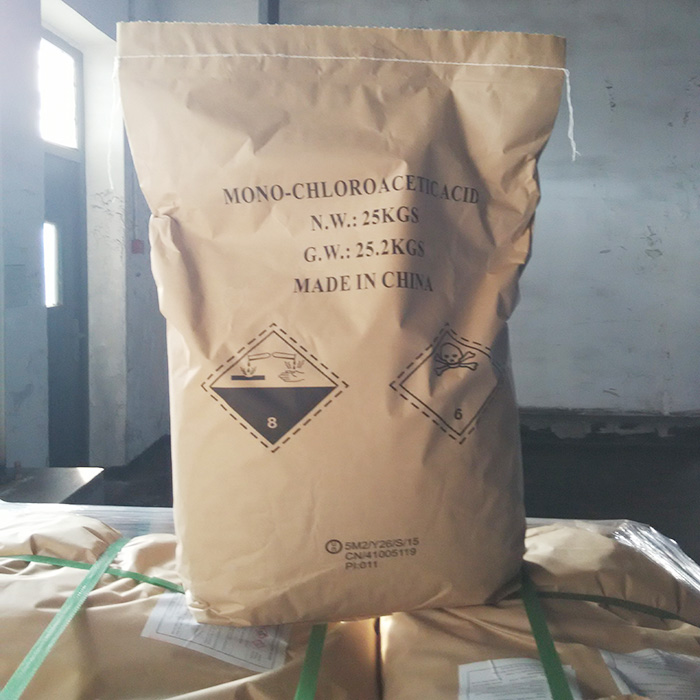

Chloroacetic acid's classification as a toxic and corrosive substance subjects manufacturing facilities, distributors, and end-users to comprehensive regulatory oversight across multiple jurisdictions. Chloroacetic acid is classified as toxic if swallowed, toxic in contact with skin, toxic if inhaled, causes severe skin burns and eye damage, may cause respiratory irritation, and is very toxic to aquatic life according to the REACH Regulation (EC) 1907/2006. These hazard classifications necessitate stringent safety protocols throughout the chemical's entire lifecycle from production through distribution to end-use applications.

Under REACH regulations, chloroacetic acid safety labeling includes hazard statements H301 (toxic if swallowed), H311 (toxic in contact with skin), H314 (causes severe skin burns and eye damage), H331 (toxic if inhaled), H335 (may cause respiratory irritation), and H400 (very toxic to aquatic life). These standardized hazard communication requirements ensure consistent safety information across all member states of the European Union.

Precautionary statements for chloroacetic acid handling include P280 (wear protective clothing, eye protection, face protection, protective gloves), P301+P310 (if swallowed immediately call a poison center or doctor), P303+P361+P353 (if on skin or hair take off immediately all contaminated clothing and rinse skin with water), P304+P340 (if inhaled remove person to fresh air and keep comfortable for breathing), and P305+P351+P338 (if in eyes rinse cautiously with water for several minutes).

The REACH regulation's substance registration requirements mandate that manufacturers and importers exceeding specified tonnage thresholds submit comprehensive dossiers documenting physical-chemical properties, toxicological data, ecotoxicological information, and exposure scenarios. Chloroacetic acid is subject to the reporting requirements of Section 313 of SARA Title III and is listed as a hazardous substance under CERCLA, creating overlapping regulatory obligations for companies operating in both European and North American markets.

Chloroacetic acid exhibits acute toxicity with classifications including acute toxicity (oral) category 3 - toxic if swallowed, acute toxicity (dermal) category 3 - toxic in contact with skin, acute toxicity (inhalation) category 3 - toxic if inhaled. The compound causes severe skin burns with pH less than 1 at 800 g/L at 20°C and is assumed to cause serious eye damage.

Tests involving acute exposure of rats, mice, and guinea pigs have demonstrated chloroacetic acid to have extreme toxicity from inhalation and moderate to high acute toxicity from ingestion. The probable lethal oral dose is 50-500 mg/kg of body weight, between one teaspoon and one ounce for a 150 lb person.

Chloroacetic acid is irritating to the skin, cornea, and respiratory tract and causes burns, and may severely damage skin and mucous membranes. Death may follow if more than 3% of the skin is exposed to this material, with other health hazards including central nervous system depression and respiratory system depression.

Damage to the respiratory tract including inflammatory changes in respiratory organs, inflammatory lesions of the nasal mucosa, metaplasia of the olfactory epithelium, and respiratory congestion have been observed in rodents chronically exposed to chloroacetic acid by inhalation, orally, and via gavage. Chronic exposure via gavage has resulted in myocarditis (inflammation of the muscular tissue of the heart wall) and mortality due to myocardial failure in rats and hepatic vacuolar degeneration in mice.

Workers handling chloroacetic acid must be properly trained and equipped, with employers required to post hazard and warning information in work areas and communicate all health and safety hazards to potentially exposed personnel. Occupational safety programs must address both acute exposure risks during normal operations and potential chronic effects from repeated low-level exposures over extended employment periods.

Manufacturing facilities must implement comprehensive medical surveillance programs for workers with potential chloroacetic acid exposure. Employees have legal rights to request copies of medical testing results related to chloroacetic acid exposure monitoring, ensuring transparency in workplace health protection programs.

Chloroacetic acid is classified as very toxic to aquatic life, requiring avoidance of release to the environment. The compound is harmful to aquatic life and very toxic to aquatic life with long-lasting effects, with the product being water soluble and likely to spread in water systems. It is also toxic to terrestrial vertebrates.

Based on vapor pressure, chloroacetic acid released in the atmosphere will reside primarily in the atmosphere where it will be photochemically degraded with a half-life of 20 days. On release to soil, chloroacetic acid based on the Koc value will have high mobility through soil, presenting risks of groundwater contamination if released in terrestrial environments.

Chloroacetic acid is readily biodegraded in screening studies using sewage or acclimated sludge inoculum, with greater than 70-90% degradation reported in 5-10 days, with biodegradation improving considerably with acclimatization. This biodegradability characteristic reduces persistence concerns in properly functioning wastewater treatment systems, though acute toxicity to aquatic organisms remains a significant hazard during accidental releases.

Toxicity to birds is significant, with the sodium salt reportedly toxic to birds and geese LD50 at 75 mg/kg, necessitating containment measures to prevent environmental releases that could impact wildlife populations.

Handling chloroacetic acid requires wearing gloves that must be inspected prior to use, with proper glove removal technique (without touching the glove's outer surface) necessary to avoid skin contact. Workers must avoid contact with skin, eyes and clothing, washing hands before breaks and immediately after handling the substance.

Self-contained breathing apparatus, vinyl or neoprene rubber gloves, goggles and protective face shield, and rubberized or acid-resistant clothing are required for chloroacetic acid handling. Respiratory protection becomes particularly critical in scenarios involving inadequate ventilation or emergency response to spills and releases.

The chemical is considered hazardous by the 2012 OSHA Hazard Communication Standard (29 CFR 1910.1200), with target organs including the respiratory system. Engineering controls including local exhaust ventilation and enclosed handling systems provide the primary line of defense against worker exposure, with personal protective equipment serving as supplementary protection when engineering controls prove insufficient.

Chloroacetic acid must be stored in a well-ventilated place with containers kept tightly closed, stored in corrosive-resistant polypropylene containers with resistant inliners. The storage class (TRGS 510) designates chloroacetic acid as non-combustible, acute toxic Category 1 and 2 / very toxic hazardous materials.

Work areas must ensure good ventilation, with workers required to wear appropriate masks in cases of inadequate ventilation and respiratory protection when necessary. Temperature and humidity control in storage areas prevents hygroscopic chloroacetic acid from absorbing atmospheric moisture, which could compromise product quality and create handling hazards through formation of corrosive aqueous solutions.

For spill containment, spillage must be collected mechanically, with materials soaked up using inert solids such as clay or diatomaceous earth as soon as possible. On land, materials should be swept or shoveled into suitable containers, with disposal of materials or solid residues required at authorized sites.

Emergency response procedures include eliminating all ignition sources from the immediate area, stopping leaks if possible without risk, preventing entry into waterways, sewers, basements or confined areas, and absorbing or covering spills with dry earth, sand or other non-combustible materials for transfer to containers.

Signs and symptoms of acute ingestion include salivation, intense thirst, difficulty in swallowing, chills, and shock, with oral, esophageal, and stomach burns common and often associated with severe pain. Acute inhalation exposure may result in sneezing, hoarseness, choking, laryngitis, dyspnea (shortness of breath), respiratory tract irritation, and chest pain.

If swallowed, victims require immediate medical attention by calling a poison center or doctor, with similar urgent medical response needed for skin contact or inhalation exposure. Emergency responders must have immediate access to safety data sheets and trained medical professionals familiar with chloroacetic acid toxicity management.

Chloroacetic acid solid is classified under UN1751 with hazard class 6.1 (+ 8), packing group II, and designated as environmentally hazardous, with hazard labels 6.1 + 8 required. Limited quantity shipping restrictions specify 500 g maximum.

The dual hazard classification reflecting both toxic (6.1) and corrosive (8) properties necessitates special packaging, labeling, and documentation requirements under international dangerous goods transportation regulations including IMDG (maritime), IATA (air), ADR (road - Europe), and DOT (road - United States) frameworks.

Chloroacetic acid must be disposed of as hazardous waste, with employers required to contact state Department of Environmental Protection (DEP) or regional EPA offices for specific disposal recommendations. Waste is classified as hazardous and should not be released into the environment, requiring disposal in accordance with European Directives on waste and hazardous waste.

Disposal methods include offering surplus and non-recyclable solutions to licensed disposal companies or dissolving/mixing the material with combustible solvents for incineration in chemical scrubbers equipped to handle chlorinated compound combustion products. Toxic gases such as hydrogen chloride, phosgene, and carbon monoxide may be generated during combustion, requiring specialized incinerators with appropriate scrubbing systems.

Manufacturing facilities generating chloroacetic acid waste streams must maintain comprehensive documentation of waste characterization, treatment, and ultimate disposal, ensuring full traceability and regulatory compliance throughout the waste management chain. The stringent regulatory framework governing chloroacetic acid reflects the chemical's significant hazard profile while enabling continued safe use in essential industrial applications when proper controls are implemented.