Ethyl chloroacetate (CAS No. 105-39-5) is a clear, colorless organic ester widely used as an intermediate in pharmaceutical, agrochemical, and fine chemical synthesis. Its reactivity and versatility make it valuable for preparing esters, amino acid derivatives, and active pharmaceutical intermediates. Because downstream reactions are sensitive to impurities, sourcing high-purity ethyl chloroacetate is essential to preserve yield, selectivity, and regulatory compliance.

Procurement takeaway: treating ethyl chloroacetate as a technical raw material—validated by certificates and analytical data—reduces process risk and quality-related rework.

For buyers seeking a clear specification and supply option, review supplier product pages such as the dedicated listing for ethyl chloroacetate from High Mountain Chem for benchmark specs and documentation. See product details on High Mountain Chem.

Focus on measurable technical attributes. A rigorous specification drives both process performance and procurement decisions.

For many synthesis routes, acceptable purity is ≥ 98%, with specialty processes requiring ≥ 99%. Lower purity often demands additional purification steps or leads to side reactions.

Always obtain a current Certificate of Analysis (CoA), Material Safety Data Sheet (MSDS/SDS), and any relevant regulatory compliance statements (REACH, GHS classifications). Verify batch numbers and analytical chromatograms when available.

Run independent spot-checks (e.g., GC) when onboarding a new supplier. Warning signs include off-odor, discoloration, moisture above spec, and incomplete or mismatched CoA information.

Supplier selection is a multi-factor decision—technical capability, transparency, and logistics are equally important.

Prefer suppliers with ISO 9001 or equivalent quality systems. A manufacturer with documented process controls will typically provide better batch-to-batch consistency than an unverified trader.

Manufacturers typically offer traceability and scale; distributors may offer smaller-lot flexibility and localized support. Match the vendor type to your operational needs.

Transparent vendors provide full specs, analytical reports, and reasonable pricing that reflects documented quality. Extremely low quotes without documentation are high-risk.

Major production centers for ethyl chloroacetate include manufacturing hubs in Asia (China, India) while global distributors maintain inventory closer to end users. Use supplier product pages (for example, High Mountain Chem’s ethyl chloroacetate listing) to benchmark purity, packaging, and available documentation before initiating trials.

Well-structured procurement reduces cost and ensures continuity of supply without sacrificing quality.

Negotiate using purity grades, minimum order quantities, and contract length. Bulk buying lowers unit cost but requires validated storage and shelf-life management.

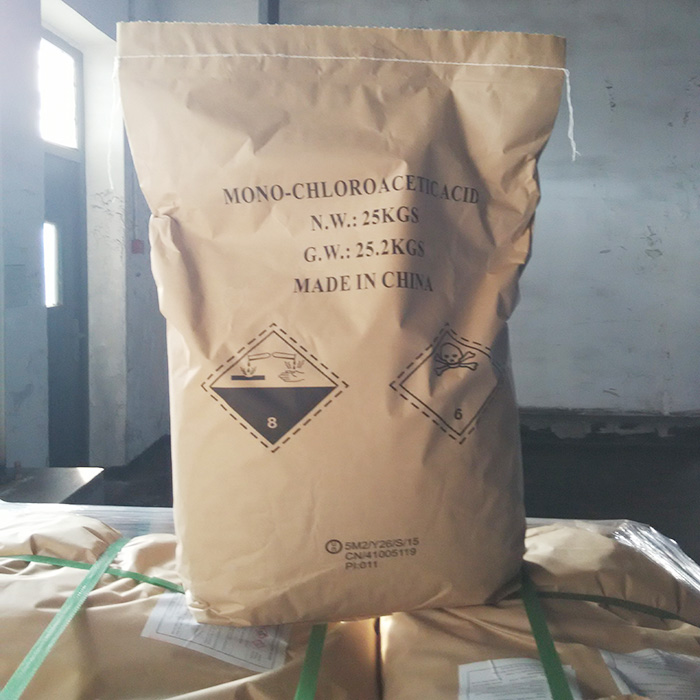

Ethyl chloroacetate is handled as a hazardous chemical—confirm UN/ADR transport classifications, packaging integrity, and carrier approvals. Properly labeled and packaged product mitigates transit damage and regulatory delays.

Schedule supplier audits (document review, plant visits or virtual audits) focused on QC labs, raw material sourcing, and waste handling. Maintain at least one qualified alternate supplier to minimize disruption.

Include environmental and compliance criteria (REACH, local chemical regulations) in your RFP. Suppliers who proactively publish compliance data simplify internal approvals and audits.

Embedding safety and compliance into procurement and operations minimizes liability and product loss.

Ethyl chloroacetate can be harmful by inhalation, ingestion, or skin contact. Use appropriate PPE (chemical-resistant gloves, goggles, and fume hood or local exhaust) and ensure employees are trained on first aid and spill response.

Confirm transport and hazard classification (e.g., UN number, GHS labeling) for both import/export and local transport. Maintain up-to-date SDS and CoA on file for audits and regulatory inspections.

105-39-5Reference: for a supplier product page that provides clear specification and documentation, consider reviewing the ethyl chloroacetate listing from High Mountain Chem: High Mountain Chem – Ethyl Chloroacetate.

Successful procurement of ethyl chloroacetate depends on rigorous specification control, supplier transparency, and adherence to handling and regulatory requirements. Use the actionable checklist above when qualifying suppliers and placing orders. Prioritize documented quality (CoA, SDS), independent verification when needed, and supply-chain resilience through audits and secondary suppliers.

If you want a ready-to-share version of this checklist or an industry-specific procurement template (e.g., for pharmaceutical synthesis or agrochemical manufacturing), I can format it for Word/Excel or WordPress with optimized meta tags and H-tags.