Sodium Chloroacetate (CAS 3926-62-3) is a white to off-white crystalline powder widely used as a reactive intermediate in organic synthesis. With the molecular formula C₂H₂ClNaO₂, it is highly soluble in water and serves as an efficient alkylating and carboxymethylating agent.

This compound’s electrophilic character makes it an ideal reagent for introducing the –CH₂CO₂⁻ group into various nucleophilic substrates. As a result, Sodium Chloroacetate plays a central role in the synthesis of herbicides, pesticides, cellulose derivatives, dyes, surfactants, and multiple fine-chemical intermediates.

For manufacturers working in agrochemical innovation, its reactivity and versatility make it one of the most important building blocks in modern crop-protection chemistry.

Sodium Chloroacetate is a strategic intermediate in the synthesis of agrochemicals, especially in herbicide and pesticide production. Its functionality supports numerous reaction pathways, enabling the construction of complex molecules used in crop-protection agents.

Herbicide production: Sodium Chloroacetate contributes to the synthesis of key herbicidal intermediates used in broadleaf weed control. Its carboxymethylation ability is essential in building structures similar to those found in well-known herbicide families.

Insecticide intermediates: It participates in synthetic routes for insecticides such as dimethoate and benazolin, which require precise molecular construction enabled by alkylation chemistry.

Plant growth regulators & related compounds: Its chemical reactivity allows producers to create compounds that influence plant metabolism or stress regulation.

Because of its broad reaction compatibility, Sodium Chloroacetate is widely chosen by agrochemical manufacturers seeking a flexible intermediate that fits multiple synthesis routes. This makes it valuable in both traditional and modern agrochemical R&D workflows.

Although its most significant impact is in agrochemicals, Sodium Chloroacetate is used across a variety of industries due to its reactivity and compatibility with different chemical systems.

Cellulose derivatives: One of its largest non-agrochemical applications is in the production of carboxymethyl cellulose (CMC), an essential thickener, binder, and stabilizer used in agrochemical formulations, coatings, detergents, and food additives.

Dyes and textile auxiliaries: Sodium Chloroacetate facilitates dye-intermediate synthesis and improves textile processing efficiency.

Surfactants and specialty chemicals: Its role in building functional groups makes it ideal for producing specialty surfactants used in formulations and cleaning products.

Pharmaceutical intermediates: It is also used in fine-chemical synthesis for API precursors and related organic compounds.

This diversity of applications increases global demand, underscoring the need for stable and reliable supply sources.

High chemical reactivity: Enables efficient synthesis of complex agrochemical molecules.

Excellent water solubility: Ensures smooth handling during production.

Cost-effective intermediate: Offers significant value compared with other alkylating agents.

Multi-route compatibility: Works across herbicide, insecticide, and growth-regulator synthesis.

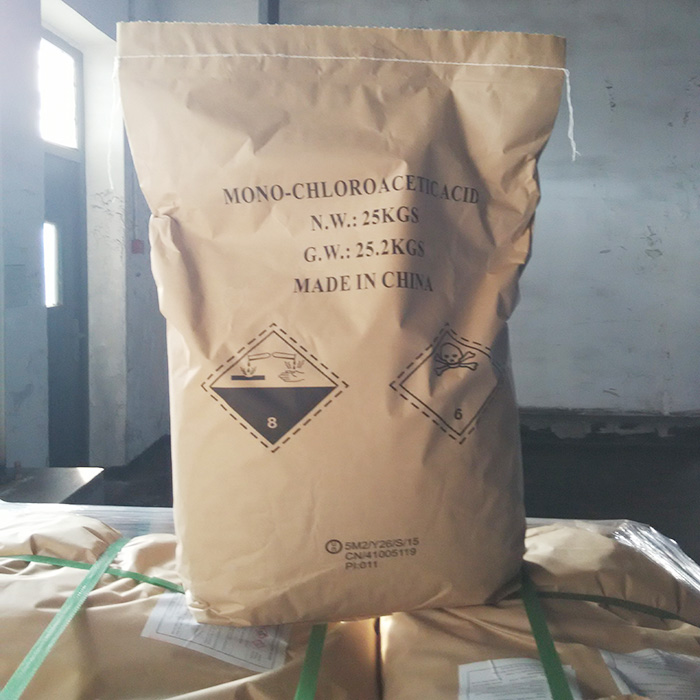

Toxicity risks: Sodium Chloroacetate can be harmful if ingested or improperly handled.

Environmental precautions: Requires controlled disposal and compliant waste management.

Regulatory oversight: Proper labeling, transport compliance, and storage procedures are essential for safe industrial use.

Manufacturers must implement strong safety protocols and ensure that the material is sourced from suppliers with robust quality systems.

Choosing the right supplier directly affects production efficiency, regulatory compliance, and final product quality. When purchasing Sodium Chloroacetate, agrochemical companies should consider:

Purity and Specification Consistency

High-purity Sodium Chloroacetate (typically ≥ 98%) ensures fewer by-products, cleaner reactions, and more predictable yields.

Quality Documentation and Batch Transparency

Certificates of analysis (CoA), SDS compliance, and production traceability are essential for agrochemical audits.

Packaging and Storage Conditions

Proper moisture-proof packaging and safe transport labeling reduce degradation risks.

Supply Reliability & Production Capacity

Because demand spans multiple industries, supply stability is crucial for large-scale agrochemical production.

For companies seeking a dependable supply partner, High Mountain Chem provides high-quality Sodium Chloroacetate with strong quality control and specifications suitable for agrochemical production. More details can be found on their product page: https://www.highmountainco.com/sodium-chloroacetate/

For R&D teams and production managers, Sodium Chloroacetate can be integrated into multiple phases of agrochemical development:

Used in substitution, alkylation, or carboxymethylation reactions.

Enables molecular modifications required for herbicide or insecticide activity.

Routine analytical testing (assay, moisture, impurities) ensures consistency.

Stable raw-material quality reduces downstream formulation challenges.

Observe SDS guidelines and ensure proper industrial hygiene measures.

Manage waste disposal according to environmental regulations.

Validate compliance for agrochemical registration and export documentation.

When these steps are implemented, Sodium Chloroacetate becomes a high-value, low-risk component of modern agrochemical development.

The performance of any agrochemical synthesis is only as strong as the quality of its raw materials. Using a trusted supplier ensures:

Consistent high purity across every batch

Accurate technical specifications

Regulatory-compliant documentation

Reliable bulk supply and delivery timelines

Competitive pricing for large-scale production needs

High Mountain Chem provides industrial-grade Sodium Chloroacetate tailored for agrochemical manufacturing. Their product is known for strong quality control and stable supply reliability, making it a suitable benchmark for procurement teams evaluating potential suppliers.

To explore their product specifications, you can visit: https://www.highmountainco.com/sodium-chloroacetate/

Sodium Chloroacetate is a cornerstone intermediate in modern agrochemical production, enabling the synthesis of herbicides, pesticides, and growth-regulating compounds. Its versatility also supports industries such as cellulose modification, dyes, surfactants, and pharmaceuticals.

For agrochemical formulators and procurement professionals, the key considerations include:

Ensuring high-purity raw materials

Verifying supplier quality and consistency

Implementing robust safety and compliance practices

Choosing reliable, experienced suppliers to support long-term production

By understanding both the technical capabilities and sourcing considerations of Sodium Chloroacetate, companies can improve efficiency, ensure compliance, and strengthen their agrochemical product pipelines.